Analysis of filter media and bulk material

On our test stand bulk materials are analyzed and classified.

Testing of the bulk material determining the optimal applications of the ts-systemfilter units, filter media, durability, clean air values and many other data leads to the selection of the customised filter apparatus.

We would be glad analyze also your bulk material on our test stand or carry out an application test to determine the appropriate filter media and the filter apparatus suitable for you. The physical properties of our filter media will be sent to you upon request.

Any questions? We are happy to advise you - contact us.

Your contact person General Inquiry

Our laboratory

Criteria for the Analysis of Bulk Materials and Filter Media (Excerpt)

![[Translate to Englisch:] Bestimmung der Schüttdichte zur Auswahl des passenden Filtermediums für das Filterelement](/fileadmin/assets/831_A.jpg)

For powdered and granular materials, the bulk density is the ratio of mass to the occupied volume. For determination, the substance in question is poured into a measuring cup of known volume and the weight is found.

Bulk density plays a major role in determining the appropriate filter media for the filter elements in the filter apparatus.

![[Translate to Englisch:] Bestimmung des Blasenpunktes (Bubble-Point) und Bestimmung der größten (und vielen) Porenabmessung zur Auswahl des passenden Filtermediums für das Filterelement](/fileadmin/assets/748_A.jpg)

The determination of the pore size gives a statement about the structure of the filter medium and allows conclusions regarding the transmittance. For solids, the transmittance is about 1/7 of the value of the »many pores«.

The bubble pressure method measures the maximum pore size of filter membranes. To carry out the measurement, a filter medium is completely soaked with a liquid of the surface tension G (dyn ● cm-1) and then a gas stream is forced through the pores to derive therefrom the mean diameter of the widest pore in μ.

The pore size plays a major role in determining the appropriate filter medium for the filter elements in the filter apparatus.

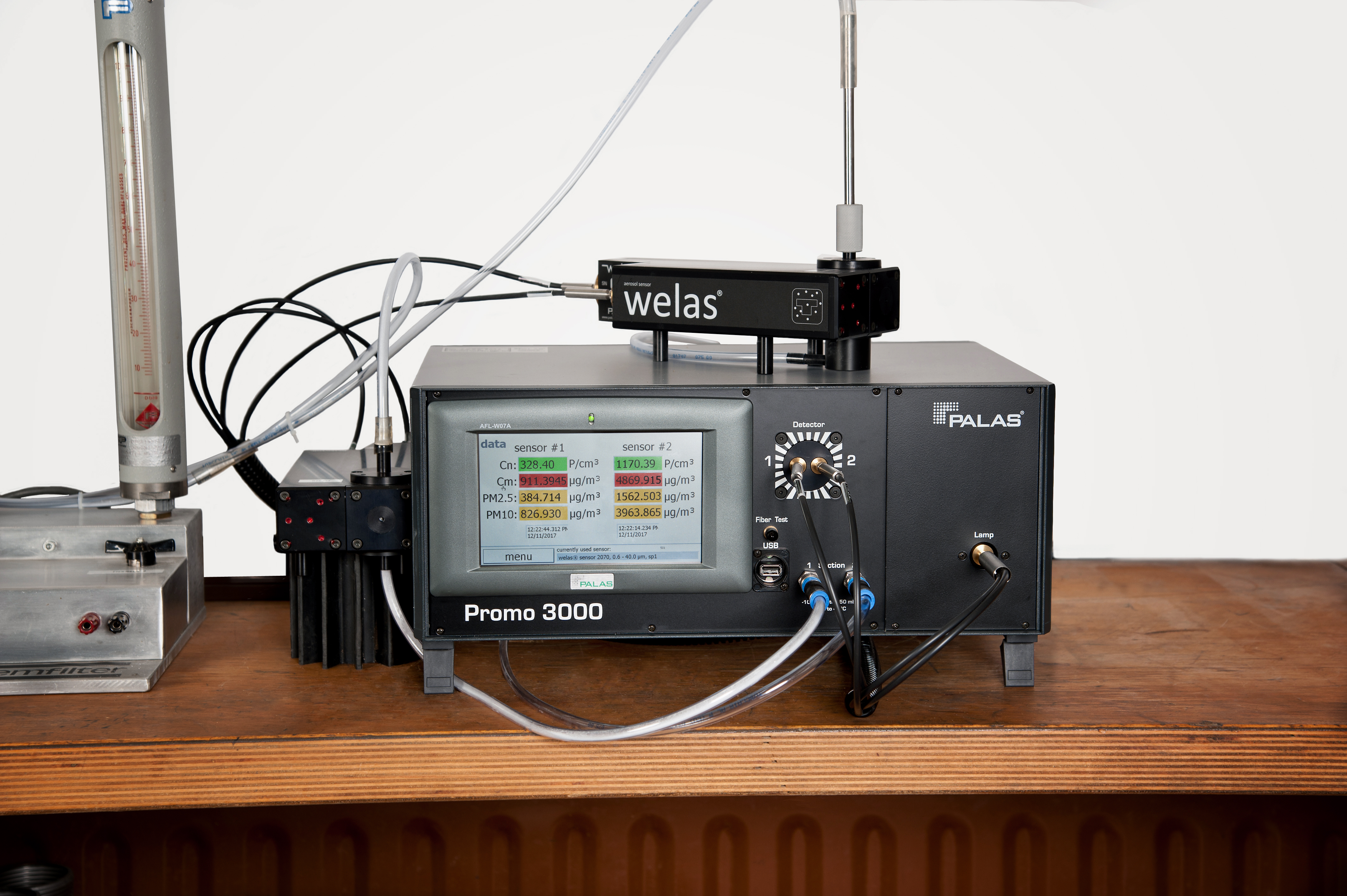

![[Translate to Englisch:] Filtermedienprüfstand mit Aerosolspektrometer zur Auswahl des passenden Filtermediums für das Filterelement](/fileadmin/assets/789_B.jpg)

The filter media test bench is used to compare various filter materials as well as for the design and optimisation of filter systems and dedusting methods by means of fast and reproducible measurements:

- Practical testing of filter media

- Reproducibility of dust dosing over longer periods of time

- Measurement of change in the separation behaviour of filter media during long-term dusting and the associated increase in air resistance

- Comparison of very different filter materials under identical test conditions

![[Translate to Englisch:] Bestimmung der Luftdurchlässigkeit zur Auswahl des passenden Filtermediums für das Filterelement](/fileadmin/assets/752_A.jpg)

The air permeability is a measure for the resistance that opposes a filter medium to a flowing vertical air flow.

The air permeability plays a major role in determining the appropriate filter medium for the filter elements in the filter apparatus.

The value of the grain density is used to determine the floating speed (bulk material) or to determine the fibre volume, pore volume and fibre density (filter medium) in accordance with DIN 112795.

Based on the grain density, the appropriate filter medium for the filter element in the filter apparatus can be selected.

The brush dispenser generates test aerosols from powders, pollen and biological agents, mass flow approx. 10 mg/h - 430 g/h. The brush dispenser is part of our filter media test bench and supports the selection of the appropriate filter medium for the filter elements in the filter apparatus.

The determination of the bursting pressure gives information about the strength of the test piece against compressive stress, especially the relationship between bursting pressure and destruction as well as limit stress, which leads to destruction (bursting). The filter medium sample is impinged up to destruction (bursting) and the pressure required for this is determined.

The bursting pressure, therefore, plays a role in the selection of the appropriate filter medium for the filter elements in the filter apparatus.

The tenacity of a filter medium is a measure for its mechanical strength. The elongation gives a statement about the elasticity of a filter medium.

The force at which the strip sample ruptures and the elongation observed at that time are determined. Tenacity and elongation play a major role in the selection of the appropriate filter medium for the filter elements in the filter apparatus.

The bending strength is a measure of the resistance of a filter medium against deflection. With the bending strength a statement about the mechanical stability of a filter medium is obtained. From this it can be deduced whether the stability should be increased by inserting a supporting tissue.

The bending strength plays a major role in the selection of the appropriate filter medium for the filter elements in the filter apparatus.

The three measured quantities thickness, basis weight and density of the medium are directly related. They give a statement about the strength of a filter medium.

The paper thickness is measured based on DIN 53855 with the Schröder dial gauge at several points and from this the mean paper thickness is determined. To determine the basis weight (DIN 53854), three square samples (20 cm x 20 cm) are to be taken across the width of the rolls and their mass must be determined. Density is expressed as the quotient of basis weight relative to thickness.

Thickness, basis weight and density play a major role in determining the appropriate filter medium for the filter elements in the filter apparatus.

The electrical resistance values (surface resistance ROT, volume resistance RDT) are a measure for the conductivity of a filter medium. This is particularly important in potentially explosive atmospheres (ATEX) in which charging the filter medium can cause an explosion.

Volume and surface resistance play a major role in determining the appropriate filter medium for the filter elements in the filter apparatus.

The friction coefficient is, among other, a measure of the adhesion of bulk materials to a filter medium.

The friction coefficient, therefore, plays an important role in establishing the appropriate filter medium for the filter elements in the filter apparatus.

Are you in need of filter units or spare parts?

Use our inquiry forms. We will send you a free and non-binding offer.

Inquiry Filter apparatus Inquiry for spare parts General Inquiry

Any questions? We are happy to advise you - contact us.